In 2018, the United States generated more than 35.7 million tons of plastic, with a recycling rate of just 8.7%. In the years since then, we have seen a boom in plastic-based items such as food packaging and personal protective equipment (PPE) which has only exacerbated the problem.

Conventional plastics use petrochemicals as a raw material, meaning every water bottle, plastic fork, or shopping bag requires the use of non-renewable fossil fuels—and that’s before the energy for production, transportation, and associated emissions are taken into account. What’s more, as much as 40% of the products made from plastic are designed to be disposable.

The problem is that plastic itself never really goes away, and its non-biodegradability means as much as 79% of all the plastics ever made remain in landfill or the wider environment. Additionally, even if plastic is recycled, it can only go through the system a handful of times before degrading so much that it is no longer of any use, meaning all plastic ends up as trash eventually.

It’s no surprise then, that people are looking for alternatives to conventional plastics, and among the materials that have risen in popularity over recent years is PLA—a biodegradable plastic made from renewable sources. However, is it really as good as it sounds?

What is PLA?

What is PLA?

PLA, or by its full name, Polylactic Acid is a bio-based polyester, commonly made from materials such as corn starch, sugar cane, and sugar beet. These plants are fermented to produce lactic acid, which then goes through the process of polymerization to create PLA. As a thermoplastic, it bears similarities to polypropylene (PP), polyethylene (PE), or polystyrene (PS), and is manufactured using techniques such as extrusion, injection molding, thermoforming, and other methods such as 3D printing using PLA filament.

PLA has been in use for almost a century, but in more recent years has been heralded as a solution to single-use plastics, specifically PET which is used for products such as disposable cups. However, PLA might not be the wonder-solution that some people are pitching it as. Let’s take a look at some of the benefits and drawbacks of PLA to understand the differences between PLA and plastic.

Source: ecomena.org

How durable is PLA plastic?

One of the major concerns that people have about bioplastic is how they hold up against their petrochemical competitors. The short answer is bio-based polymers tend to not be as strong as fossil fuel-based polymers. That said, they often don’t need to be. PLA is most frequently being used as an alternative to non-bio plastics in low-stress applications like cups, food packaging, and bags, where it is more than strong enough for a single-use.

Additionally, compostable doesn’t mean that it’s going to start breaking down in your hands or as you rush back from the store. In fact, it can take much longer than expected for PLA to decompose, which we’ll get to after looking at some of its benefits.

Where PLA has an advantage over plastic

One benefit of PLA, when compared with plastics, is that it is made from renewable resources. Rather than crude oil, PLA requires crops that can be grown year after year. What’s more, these crops draw down carbon when they are grown, so are pulling greenhouse gases out of the atmosphere to make PLA.

Another pro of PLA is that it is biodegradable. More specifically, it is biodegradable when processed using the correct composting conditions in specialized industrial composting facilities where it will break down into water, carbon dioxide, and composite in six months or less. Additionally, it can also be decomposed in specialist facilities that use high temperatures and PLA-degrading enzymes. It is valuable to note that there are very few composting facilities that accept PLA.

The cons of PLA

The resources required to make PLA are renewable but are not without their drawbacks. Firstly, there are ethical concerns—should viable food crops be used to make single-use plastics when so many people still suffer from hunger and malnutrition? What’s more, these crops still require inputs such as water; labor; and even petrochemicals within fertilizer, pesticides, and machinery. Further energy is then used within the manufacturing process and transport the PLA products, many of which are destined to be used once and thrown in the trash.

It is worth noting at this stage that the monoculture crop farms used to grow the raw materials used in PLAs are also highly damaging to the environment. They are associated with large-scale deforestation, a reduction in biodiversity related to both flora and fauna, they significantly affect weather patterns and rainfall, directly contributing to climate change, and are responsible for a raft of other issues from soil degradation to rising economic inequality.

When it comes to dealing with the waste created by PLAs, the picture doesn’t get much better. Whilst PLA is technically biodegradable, when not diverted to industrial compost facilities, it can take a very long time to break down. In a landfill, where many PLA products will end up, it can potentially take hundreds of years to—similar to regular plastics. Additionally, the types of facilities required for successful biodegradation are in short supply, meaning more PLA ends up in landfill or the environment that is recycled or decomposed.

That said, it does decompose rather than just breaking down into smaller particles of plastic, which is far less damaging to ecosystems considering the recent revelations surrounding microplastics and nanoplastics. However, unlike natural biomass that adds nutrients to the soil as it breaks down, PLA adds nothing of value and can instead increase the acidity due to the lactide created as lactic acid breaks down.

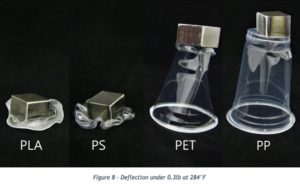

PLA’s low melting point is, theoretically, a positive for recycling, but in real-world applications, PLA products can contaminate the conventional plastics recycling process which requires higher temperatures. At best, this results in PLA being separated out for disposal, but at worst, it can cause entire batches of other plastics to be tossed in the trash as well due to contaminated feedstock. Additionally, in order to be recycled, PLA would need to be collected separately or have the ability to be sorted from other types of plastics. It also may only be possible to recycle with a specialty recycler as our current recycling infrastructure is not equipped to handle the separation and processing of PLA.

Source: creativemechanisms.com

PLA or plastic?

Overall, when looking at the differences between PLA and PET or other petrochemical plastics, it is difficult to argue that PLAs are any better than their more conventional counterparts. In fact, there is mounting evidence to suggest that they may be more harmful to the environment than standard plastic products.

PLA may use renewable sources for raw materials, but these come at an additional cost, not only requiring significant usage of non-renewable resources but also negatively impacting the environment in a number of ways. Additionally, while PLA may mitigate the growing microplastics problem, it can barely be classed as compostable under existing infrastructures.

However, these negatives feed into a larger issue, namely, the perpetuation of single-use products and a shifting of the narrative away from reduction and reuse. The fact is that any single-use product is far from an ideal solution to our existing waste generation issues, and reducing consumption or shifting towards reusable packaging must be the priority.

Finally, instead of trying to find materials that will allow us to continue our current consumption habits, it is important to take time to figure out better ways to consume and cut out single-use packaging entirely.

For more information on how your business can reduce plastic waste, contact our TRUE Advisors today. Additionally, subscribe to the RTS blog for more news and insights on sustainable waste management.